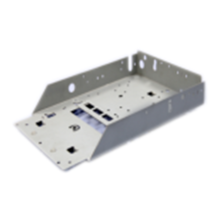

Customized Aluminum Casting Base with Sand Blasting Finish for Home Care Robot

- Productivity:

- 10000PCS/Week

- Place of Origin:

- China Mainland

- Supply Ability:

- 10000PCS/Week

- Certificate:

- SGS, ISO 9001

Basic Info

Model No.: 160816001

Product Description

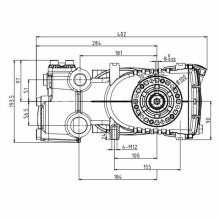

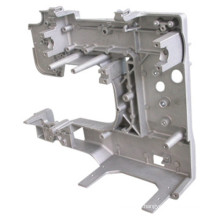

Model NO.: 160816001 Die Casting Method: Precision Die Casting Machining: Machining Center Surface Preparation: Polishing Tolerance Grade: 6 Certification: SGS, ISO 9001:2008 Type: Die Casting Surface Roughness: Ra0.4-3.2 MOQ: 100PCS Export Market: Global Certificate: ISO9001:2000 Transport Package: as Per Customer′s Requirements Origin: China Mainland Die Casting Machine Type: Hot Chamber Die Casting Machine Application: Hardware Material: Aluminum Pressure Chamber Structure: Horizontal Casting Surface Quality Level: 2 Model No.: Gch15006 Tolerance: 0.005-0.1mm Software: PRO/E, Auto CAD, Solid Work, Ug, CAD, Cam QC System: 100% Inspection Before Shipment Business Type: Factory Manufacturing Trademark: No Specification: Depend on the quantity of the order HS Code: 7610900000 Customized Aluminum Casting base with sand blasting finish for Home care robot

Product Description:

1. OEM and ODM 100%

2. High quality

3. Best service and best products

4. Advanced technology and equipment.

Product features:

1. Application: Auto parts/Engine parts/Agriculture equipment parts/LED Lighting parts/Train parts and so on.

2. Material: 6061,8407, SKD11 or per customer's requirements.

3. Die casting equipment: 180T/280T/400T/600T/800T/1000T;

4. Mold material: H13/1.2344

5. Mold life: 50, 000 shots;

6. Main process:

1> Die casting;

2> Deburring;

3> Sandblasting;

4> Machining;

5> Leakage test;

6> Surface treatment

Quick introduction about our capability:

Our company is specialized in die casting products& CNC machining parts. We provide One-stop Service, Please kindly check our details.

1. Aluminum Die Casting Mold Material: 6061,8407, SKD11 or per customer's requirements...

2. Mold Design: According to Technical Drawings or Samples.

3. Mold Lead Time: 20 ~ 30 days

4. OEM and ODM orders are all Welcomed.

5. High Quality & Competitive Price & prompt delivery.

6. Advanced equipment and excellent R&D Team, Highly skilled manufacturing

Process, Strict quality Control System.

How we can keep the high quality parts always?

1.All our material will be tested by SGS before production

2. Full control of process:

(1).During the part production,our QC worker will inspect the part size every one hour,this will help us to keep the correct tolerance during production

(2). When the parts machining finished,they will be arranged to have surface finished(such as anodize or powder coated),after that,our QC worker will

inspect the parts again,because after surface finished,part tolerance may be difference sometimes,if there is any defective parts we found,we will pick them out directly

(3). Before shipping,our package worker will check the part surface and see if there is any scrach or any other thing that affect the part looking,if yes,pick them out.

What can we do for you?

1.Professional,Competitive price and Fast delivery time

We engaged in this area for almost 10 years, skilled engineer can help you process the project well and perfect,

also we own our factory,that we can control the cost and delivery time very well.We can try best to meet your request.

Protect our customer profit well.

Even we have very strictly quality control system,but we still can`t promise every part you received will 100% perfect,

so if there is any defective part you received,you just need to offer us the evidence(such as picture),we will check and

confirm it.After that,we will repair or redo them.

Because of our strictly quality control system,so we have the confidence to promise our customer with this.Please kindly

noted that it`s our advantage compare with others,we realize that only the high quality and good service can keep the friendly

and long-term business relationship with our customer and it`s also the only way for an enterprise to be existed...

Contact information:

Contact person:Stephen Song

Tel:86-(755)-29931388

Fax:86-(755)-29931288

Add: 1st Building, A area, Buyong Industiral Zone, Shajing Street, Bao'an district, Shenzhen, China. Contact us if you need more details on Aluminum Base. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminum Casting、Casting Part. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Description:

1. OEM and ODM 100%

2. High quality

3. Best service and best products

4. Advanced technology and equipment.

Product features:

1. Application: Auto parts/Engine parts/Agriculture equipment parts/LED Lighting parts/Train parts and so on.

2. Material: 6061,8407, SKD11 or per customer's requirements.

3. Die casting equipment: 180T/280T/400T/600T/800T/1000T;

4. Mold material: H13/1.2344

5. Mold life: 50, 000 shots;

6. Main process:

1> Die casting;

2> Deburring;

3> Sandblasting;

4> Machining;

5> Leakage test;

6> Surface treatment

Quick introduction about our capability:

| Certificate: | ISO9001: 2000 |

| OEM & ODM products range: | Auto parts, Engine parts, Agriculture equipment parts, Lighting parts, Train parts, etc. |

| Die casting equipment capability: | 180T/280T/400T/600T/800T/1000T |

| Product weight: | From 0.05~10kg |

| Machining equipment: | CNC, Lathe machine, Milling machine, Drilling machine, and so on |

| Test equipment: | Optical Spectrum Analyzer, CMM, Hardness test equipment, Tensile test machine |

| Surface treatment: | Powder coating, Anodization, Chrome plating, Painting, Sand blasting |

Our company is specialized in die casting products& CNC machining parts. We provide One-stop Service, Please kindly check our details.

1. Aluminum Die Casting Mold Material: 6061,8407, SKD11 or per customer's requirements...

2. Mold Design: According to Technical Drawings or Samples.

3. Mold Lead Time: 20 ~ 30 days

4. OEM and ODM orders are all Welcomed.

5. High Quality & Competitive Price & prompt delivery.

6. Advanced equipment and excellent R&D Team, Highly skilled manufacturing

Process, Strict quality Control System.

How we can keep the high quality parts always?

1.All our material will be tested by SGS before production

2. Full control of process:

(1).During the part production,our QC worker will inspect the part size every one hour,this will help us to keep the correct tolerance during production

(2). When the parts machining finished,they will be arranged to have surface finished(such as anodize or powder coated),after that,our QC worker will

inspect the parts again,because after surface finished,part tolerance may be difference sometimes,if there is any defective parts we found,we will pick them out directly

(3). Before shipping,our package worker will check the part surface and see if there is any scrach or any other thing that affect the part looking,if yes,pick them out.

What can we do for you?

1.Professional,Competitive price and Fast delivery time

We engaged in this area for almost 10 years, skilled engineer can help you process the project well and perfect,

also we own our factory,that we can control the cost and delivery time very well.We can try best to meet your request.

Protect our customer profit well.

Even we have very strictly quality control system,but we still can`t promise every part you received will 100% perfect,

so if there is any defective part you received,you just need to offer us the evidence(such as picture),we will check and

confirm it.After that,we will repair or redo them.

Because of our strictly quality control system,so we have the confidence to promise our customer with this.Please kindly

noted that it`s our advantage compare with others,we realize that only the high quality and good service can keep the friendly

and long-term business relationship with our customer and it`s also the only way for an enterprise to be existed...

Contact information:

Contact person:Stephen Song

Tel:86-(755)-29931388

Fax:86-(755)-29931288

Add: 1st Building, A area, Buyong Industiral Zone, Shajing Street, Bao'an district, Shenzhen, China. Contact us if you need more details on Aluminum Base. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminum Casting、Casting Part. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Die casting components

Premium Related Products

Other Products

Hot Products

Custom wholesale titanium lug nut / titanium nuthigh strengh steel weld nutHigh precision brass nutsWhite zinc plated hex boltHigh strength carbon steel c1022 screwshenzhen hardware multi-metal T Head BoltsCustom high strength anchor boltcarbon steel 10.9 carriage boltStainless Steel thumb screwCold heading machined hex head boltChina manufactrer cold heading nutChina supplier copper bolt and fastener(bolt and nut)Carbon steel self drilling roofing screw with EPDM washerStainless steel cnc partsStainless Steel square lock cage nuthight quality stainless steel anti theft bolt with Special Head M8*20