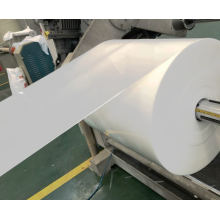

Injection molding ldpe plastic pla abs product

| Packaging: | - Proper packing foam bag/sheet protect the part - Put the part on the PET tray - Pack the tray and products into and carton box - Seal the carton box with tapes - Lay the boxes on the pallet with 8 corners protector - Band the box and pallet together - |

|---|---|

| Productivity: | 10000pcs/week |

| Brand: | FCE |

| Transportation: | Express,Ocean,Land,Air |

| Place of Origin: | Jiangsu |

| Supply Ability: | 100000 Piece/Pieces per Week |

| Certificate: | ISO9001 |

| Port: | Shanghai/Ningbo |

Click on the follow link to find out more information: https://www.fcesz.com/multi-k-injection-moulding/

Company Info

- Company Name: Suzhou FCE precision electronics Co., LTD

- Representative: Jie Zhiguo

- Product/Service: Injection Molding , Sheet Metal Processing , Cnc Machining , Rubber Silicone , 3D Printing , Mechanical ODM

- Capital (Million US $): 1000000RMB

- Year Established: 2019

- Total Annual Sales Volume (Million US $): US$1 Million - US$2.5 Million

- Export Percentage: 81% - 90%

- Total Annual Purchase Volume (Million US $): US$1 Million - US$2.5 Million

- No. of Production Lines: 5

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 1,000-3,000 square meters

- Factory Location: 4# plant,JiangPu Road No.75, Suzhou, Jiangsu, China

- Contact Person: Mr. lee jie

- Tel: 86--15051470515

Premium Related Products

Other Products

Hot Products

Custom wholesale titanium lug nut / titanium nuthigh strengh steel weld nutHigh precision brass nutsWhite zinc plated hex boltHigh strength carbon steel c1022 screwshenzhen hardware multi-metal T Head BoltsCustom high strength anchor boltcarbon steel 10.9 carriage boltStainless Steel thumb screwCold heading machined hex head boltChina manufactrer cold heading nutChina supplier copper bolt and fastener(bolt and nut)Carbon steel self drilling roofing screw with EPDM washerStainless steel cnc partsStainless Steel square lock cage nuthight quality stainless steel anti theft bolt with Special Head M8*20