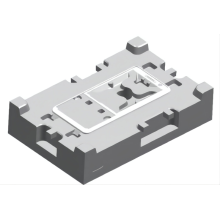

Virtual Reality (VR) Plastic Injection Mould

- Productivity:

- 200PCS/Year

- Place of Origin:

- China

- Supply Ability:

- 200PCS/Year

- Certificate:

- CE

Basic Info

Model No.: virtual reality

Product Description

Model NO.: virtual reality Surface Finish Process: Polishing Plastic Material: ABS Application: Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware, Medical Design Software: Pro-E Certification: CE Customized: Customized Packing: Carton, Pallet, as Per Customer Requirement Capacity: 30PCS/Month Transport Package: Cartons & Pallets Origin: China Shaping Mode: Plastic Molding Die Mould Cavity: Multi Cavity Process Combination Type: Single-Process Mode Runner: Hot Runner Installation: Semi Fixed Standard: DME Trade Mark: Kylt Raw Materials: Steel,Aluminum, Magnesium etc Trademark: KYLT Specification: CE, ROHS, SGS HS Code: 8480410090 KYLT Good Quality Customize Precision Virtual Reality(VR) plastic injection mould, CE/SGS/ROHS certification is allowed.

KYLT making injection molds of Plastic & Zinc(Zamak), Lead(Pb) alloy and provide all kinds of plastic parts as per clients drawings or samples.

KYLT engineer have over 10years making molds for Euro clients, familiar with DME,HASCO mold making standard.

1, Design & Engineering:

KYLT offers integraeted solutions for each of the development process, from initial concept design and prototyping to product validation.

--2D software we use:

AUTOCAD

Adobe Acrobat

--3D software we use:

Pro/engineer

Solidworks

UG

2, Prototyping:

A proper prototype can save time and money by avoiding costly mistakes before mold making.

Most customers choose this before they start with a complete set of product, including many components.

KYLT can also use the Rapid Prototype model to decide on the parting line, ejector Pins, and gate location.

We mostly use Stereolithography (SLA) and CNC prototyping, you can choose either of them to meet your needs.

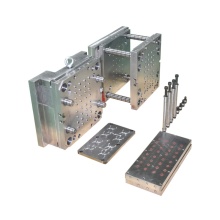

3, Mold-making & Molding:

KYLT located in Molds making town, have excellent supply chain from design to finish of moulds. We can arrange and schedule

CNC,EDM and other machines flexibly to avoid making processes delay.

4, Secondary operation:

Whenever you need more than just a plastic part, KYLT offers in house a full "turn key" secondary operation, from decorating to machining to sepcial packaging.

Painting

Pad printing

Silk screen printing

Bonding and glueing

Drilling

Welding

Labeling

Assembly

Custom packing

5, Quality:

Our QC personnel is delicated to the quality of our products.

Quality is fully integrated throughout our entire organization, from top management driven to total involvement by all production employees. Our Quality manual has documented procedures to provide in progress working quality checks.

When a product that is below standards is found, QC work with the manufacturing and engineering department tocome to an immediate resolution.

Plastic materials : ABS, PA etc

Mainly used to mold all kinds of household, automobile, electronic plastic parts.

For more information about KYLT plastic molding and plastic injection molds, please visit: www.cnkylt.com www.zamakcast.com Contact us if you need more details on Plastic Injecton Mould. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Virtual Reality Plastic Moulding、Vr Precision Plastic Parts. If these products fail to match your need, please contact us and we would like to provide relevant information.

KYLT making injection molds of Plastic & Zinc(Zamak), Lead(Pb) alloy and provide all kinds of plastic parts as per clients drawings or samples.

KYLT engineer have over 10years making molds for Euro clients, familiar with DME,HASCO mold making standard.

1, Design & Engineering:

KYLT offers integraeted solutions for each of the development process, from initial concept design and prototyping to product validation.

--2D software we use:

AUTOCAD

Adobe Acrobat

--3D software we use:

Pro/engineer

Solidworks

UG

2, Prototyping:

A proper prototype can save time and money by avoiding costly mistakes before mold making.

Most customers choose this before they start with a complete set of product, including many components.

KYLT can also use the Rapid Prototype model to decide on the parting line, ejector Pins, and gate location.

We mostly use Stereolithography (SLA) and CNC prototyping, you can choose either of them to meet your needs.

3, Mold-making & Molding:

KYLT located in Molds making town, have excellent supply chain from design to finish of moulds. We can arrange and schedule

CNC,EDM and other machines flexibly to avoid making processes delay.

4, Secondary operation:

Whenever you need more than just a plastic part, KYLT offers in house a full "turn key" secondary operation, from decorating to machining to sepcial packaging.

Painting

Pad printing

Silk screen printing

Bonding and glueing

Drilling

Welding

Labeling

Assembly

Custom packing

5, Quality:

Our QC personnel is delicated to the quality of our products.

Quality is fully integrated throughout our entire organization, from top management driven to total involvement by all production employees. Our Quality manual has documented procedures to provide in progress working quality checks.

When a product that is below standards is found, QC work with the manufacturing and engineering department tocome to an immediate resolution.

Plastic materials : ABS, PA etc

Mainly used to mold all kinds of household, automobile, electronic plastic parts.

For more information about KYLT plastic molding and plastic injection molds, please visit: www.cnkylt.com www.zamakcast.com Contact us if you need more details on Plastic Injecton Mould. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Virtual Reality Plastic Moulding、Vr Precision Plastic Parts. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Injection Moulds

Premium Related Products

Other Products

Hot Products

Custom wholesale titanium lug nut / titanium nuthigh strengh steel weld nutHigh precision brass nutsWhite zinc plated hex boltHigh strength carbon steel c1022 screwshenzhen hardware multi-metal T Head BoltsCustom high strength anchor boltcarbon steel 10.9 carriage boltStainless Steel thumb screwCold heading machined hex head boltChina manufactrer cold heading nutChina supplier copper bolt and fastener(bolt and nut)Carbon steel self drilling roofing screw with EPDM washerStainless steel cnc partsStainless Steel square lock cage nuthight quality stainless steel anti theft bolt with Special Head M8*20